We follow the principle that only top quality ensures the maximum acceptance of recycled plastics in closed-loop systems. For this reason, we exclusively utilise homogeneous cast-on parts, edge offcuts and used homogeneous plastics for our Sysplast compounds. By means of strict production norms and continuous controls, right through to specific test reports for each individual batch, we ensure the quality that you require. To this end, we are constantly developing our know-how and our machinery. As a result, we are able today to manage the complete waste stream for metallised plastics with our partner companies in the energenta corporate group – from disposal and separation to the recycling of the metal and plastic contingents. We had the opportunity to demonstrate this competence in the framework of the research alliance ‘ForCYCLE – Rohstoffwende Bayern’. In the following video, you can see exactly how it works.

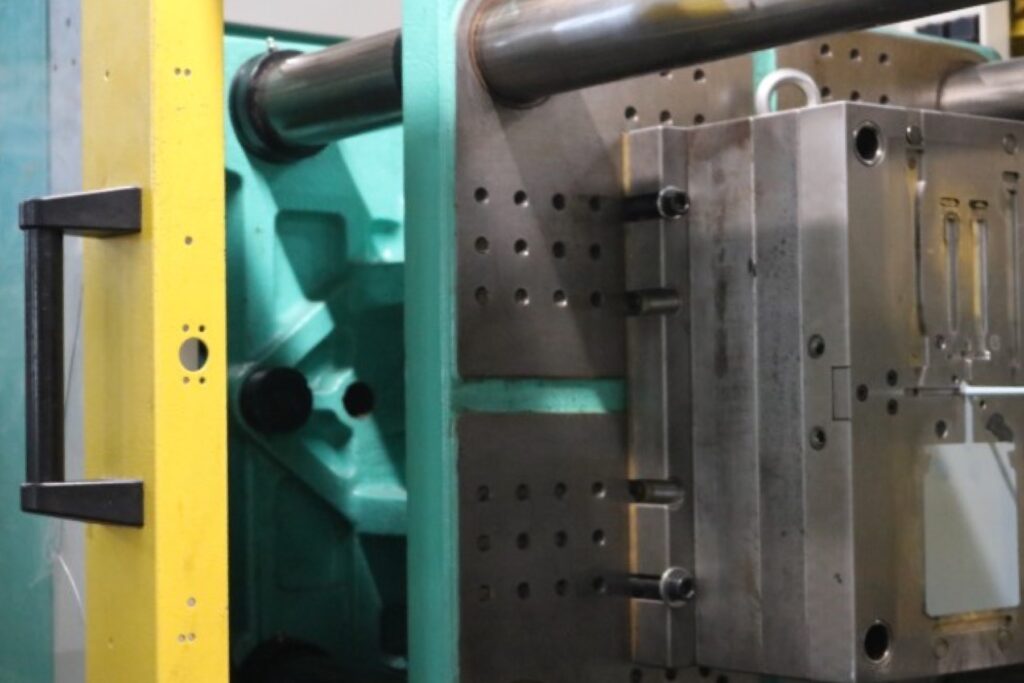

Injection moulding test plates

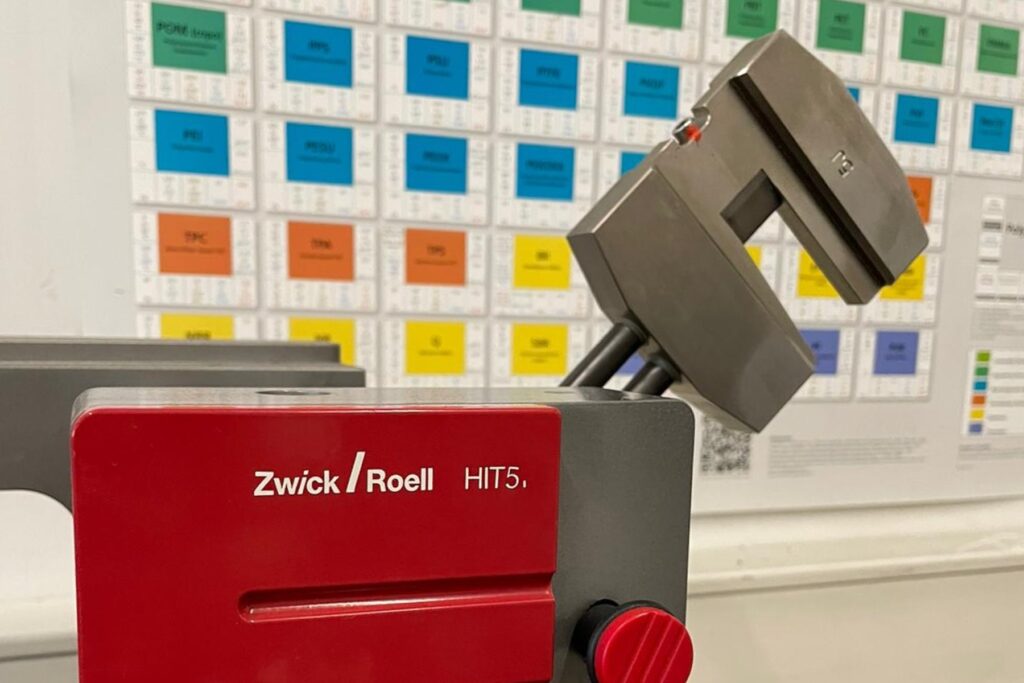

Testing apparatus for notched-bar impact strength

We are part of the solution:

the recycling of metals from metal–plastic composites and hybrid materials:

The products we offer and what they are used for:

Overview of our products:

- Sysplast® PS-HI (HIPS) – substitute for new material for visible parts

- Sysplast®ABS 75 – for most normal industrial applications

- Sysplast® ABS 100 – for technical components (e.g. all types of housings)

- Sysplast® ABS 100 E – for extrusion applications

- Sysplast® ABS 100 G – closed-loop regranulate from recycled electroplated parts

- Sysplast® ABS 150 – substitute for new material for visible parts

- Sysplast® PC-ABS – substitute for new material for visible parts